Fanblade De-Icer

Reliable de-icing without additional agents and devices

compact transport

Effective cost-cutter

This system developed by Quickloading is under utility model protection and de-ices the fan blades reliably without the need for additional, expensive heaters – at unrivalled prices.

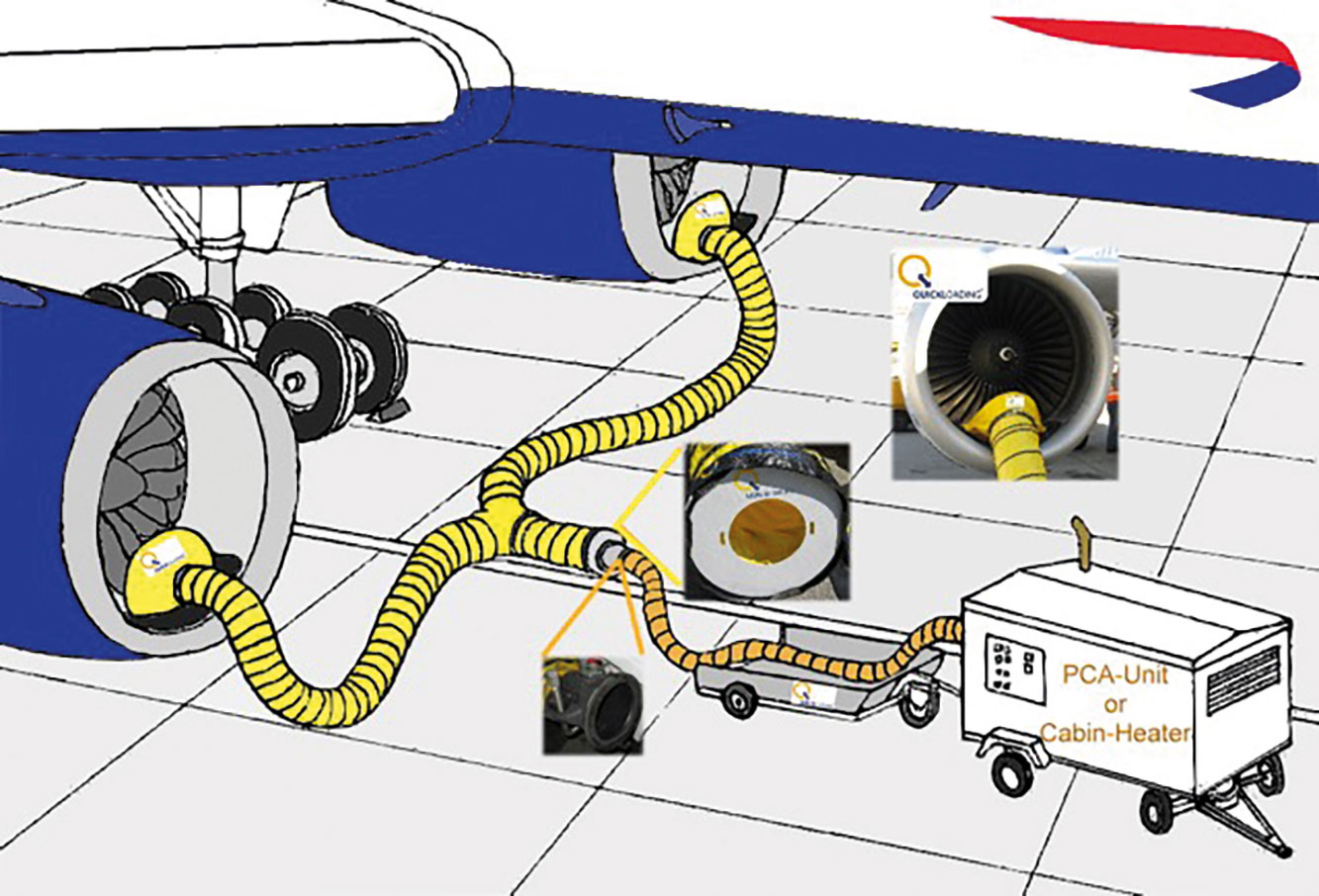

Running conventional aircraft heaters is very expensive and staff-intense; conventional de-icing agents are not allowed for engines to make sure sensors and delicate parts are not damaged. The Quickloading De-Icer is sensationally simple and cost-saving. It works completely without engine as the hot air from the RAM air, the waste heat of the aircraft, is used and transferred into the engines. The special contoured nozzle de-ices the engine fully automatically. At arrival, the staff inserts the contoured nozzle into the engine intake, removes it again before departure, and in the meantime has time to take care of processing the aircraft.

Details

- Reliable de-icing without additives or additional devices

- unrivalled low price – only a quarter of the costs of conventional devices

- fully automatic function without staff deadlock

- designed to be operated by one person, makes a quick setting-up and taking-down possible – environmental friendly through use of the waste air blown out of the aircraft (RAM-Air)

- aircraft maintenance manual compliant

HEATER ADAPTER FOR FANBLADE DE-ICING

THE AIR CONDITIONING FANBLADE DE-ICING WITH QUICKLOADING EQUIPMENT WAS DEVELOPED FOR OPERATION BY ONE PERSON.

With the power of one air conditioning unit you cannot only de-ice one but two engines at the simultaneously.

The Use

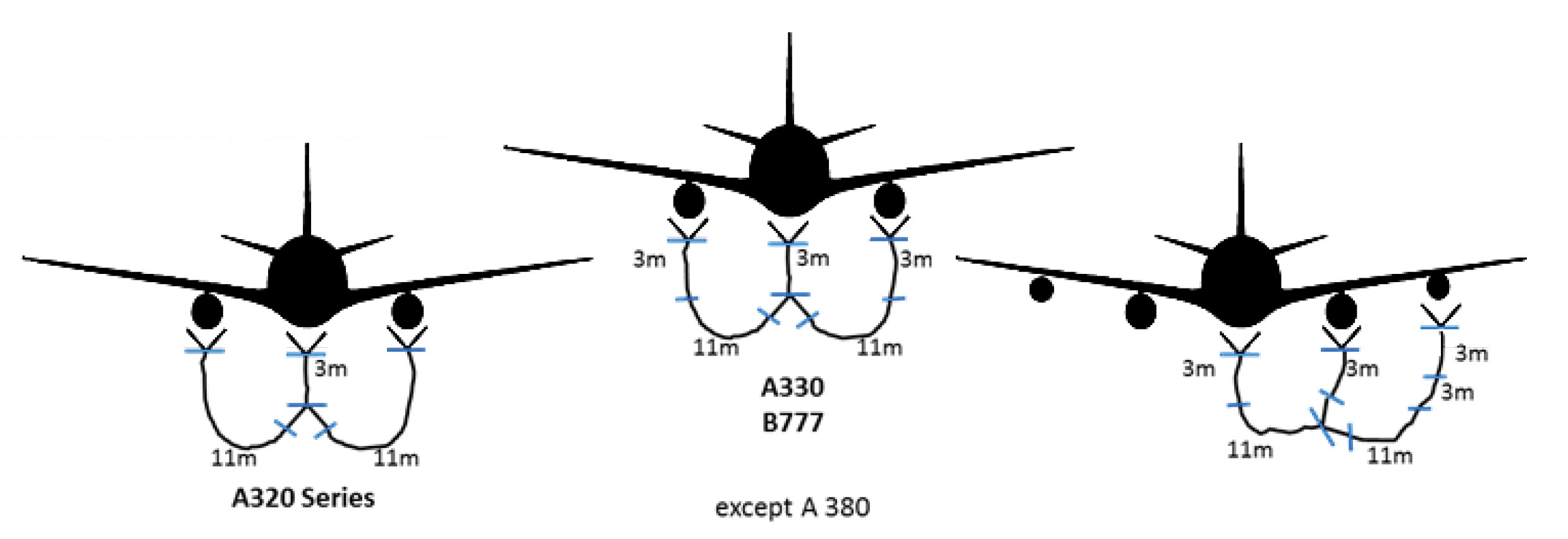

The Quickloading air conditioning adapter and 2 contoured nozzles make it possible to de-ice two engines simultaneously.

The heather / air conditioning unit only has to be positioned once and by the simultaneous admission of two engines, the time needed is reduced remarkably!